In the field of electronic semiconductors, our flow meter products have helped customers from Xi’an Taijin Industrial Electrochemical Technology Co., Ltd. solve the difficulties encountered in the Qinghai Electronic Materials project.

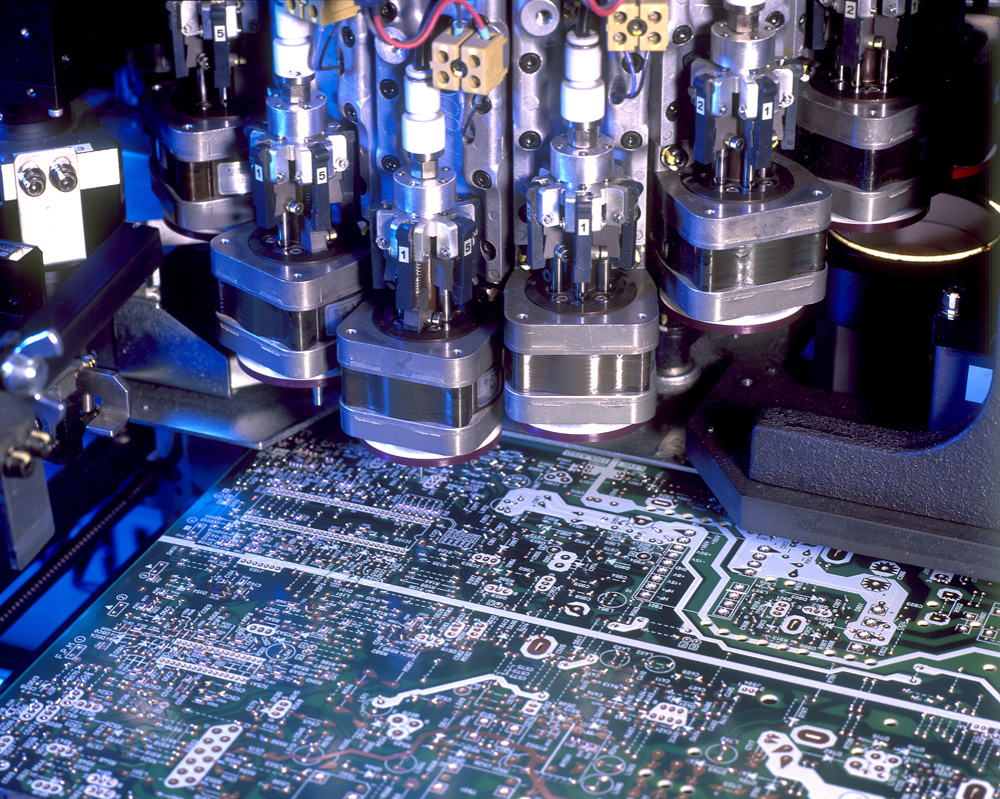

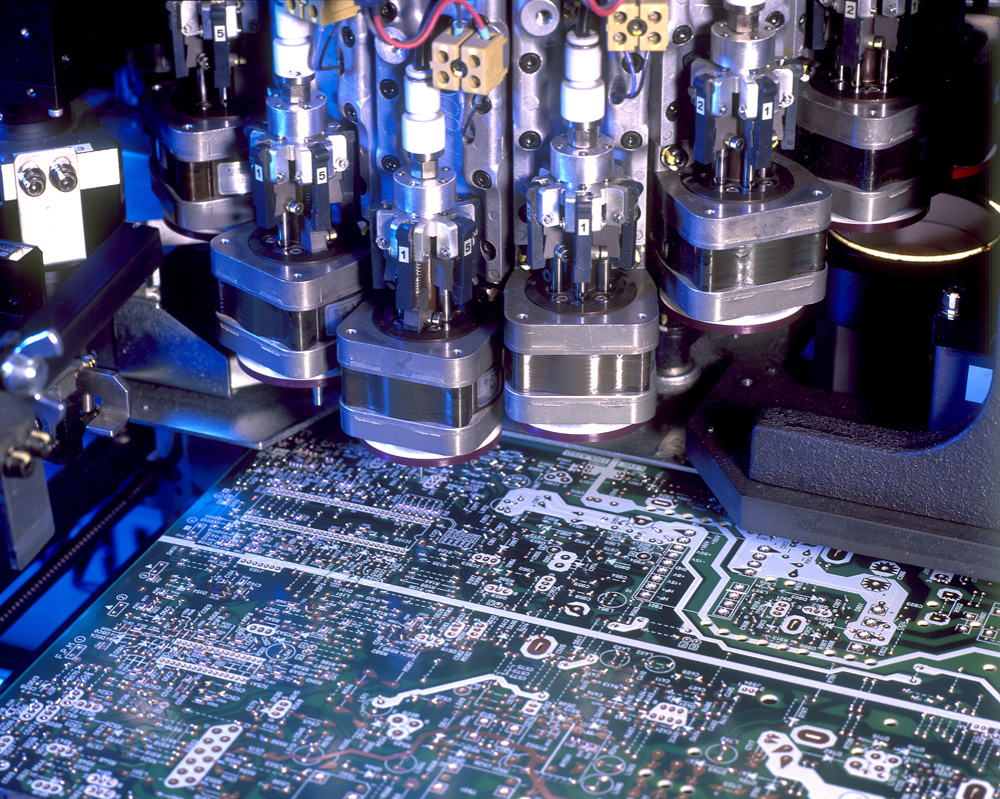

The electronics and semiconductor industry, a cornerstone of modern technology, relies on precision, accuracy, and innovation. Field instruments and industrial measuring devices play a pivotal role in the fabrication, testing, and quality assurance of electronic components and semiconductor materials. Here’s an overview of key instruments used in this sector, organized under five subheadings:

1. Dimensional Measurement and Inspection

Optical Profilometers: These electrical and electronic measuring instruments provide non-contact measurement of the surface topography of semiconductor wafers and electronic components, offering insights into surface roughness, flatness, and layer thickness with nanometer precision.

Scanning Electron Microscopes (SEMs): SEMs are crucial for high-resolution imaging and analysis of semiconductor structures, enabling the inspection of nanoscale features and defects that could impact device performance.

2. Electrical and Magnetic Property Analysis

Parametric Analyzers: These sophisticated devices measure the electrical properties of semiconductors, such as current-voltage (I-V) characteristics, capacitance-voltage (C-V) profiling, and resistance, essential for device characterization and quality control.

Hall Effect Measurement Systems: Utilized to assess the electrical conductivity and mobility of carriers within semiconductor materials, these systems are vital for understanding and optimizing semiconductor performance.

3. Chemical Composition and Contamination Analysis

Secondary Ion Mass Spectrometry (SIMS): SIMS is a powerful technique for analyzing the composition and impurity levels in semiconductor materials, providing depth profiling capabilities to detect contaminants that could adversely affect device performance.

X-ray Photoelectron Spectroscopy (XPS): XPS is used to determine the elemental composition and chemical states on the surface of materials, crucial for analyzing thin films, interfaces, and surface treatments in semiconductor manufacturing.

4. Thermal Properties and Stress Analysis

Differential Scanning Calorimetry (DSC): DSC measures how a material’s heat capacity changes with temperature, providing insights into thermal transitions that are critical for understanding the behavior of polymers and composite materials used in electronics.

Thermomechanical Analysis (TMA): TMA assesses the dimensional changes of a material as a function of temperature, offering valuable data on thermal expansion, which is essential for managing thermal stresses in electronic devices.

5. Film Thickness and Refractive Index Measurement

Ellipsometers: These instruments measure the thickness and optical properties of thin films used in semiconductor devices by analyzing the change in polarization of light reflected from the film surface, providing critical data for process control and optimization.

Reflectometers: Used for measuring the thickness of thin films and coatings by analyzing the intensity of reflected light, reflectometers are essential for ensuring uniformity and quality in layers critical to semiconductor device function.

Conclusion

The electronics and semiconductor industry’s continuous push towards smaller, faster, and more efficient devices demands the use of precise and advanced field instruments and industrial measuring devices. These tools enable the detailed analysis and quality control necessary to meet the stringent standards of the industry, driving innovation and ensuring the reliability of electronic components and semiconductor materials. As technology advances, the development of new measurement techniques and instruments will remain integral to the industry’s success.

Smart Pressure Transmitters

Smart Pressure Transmitters