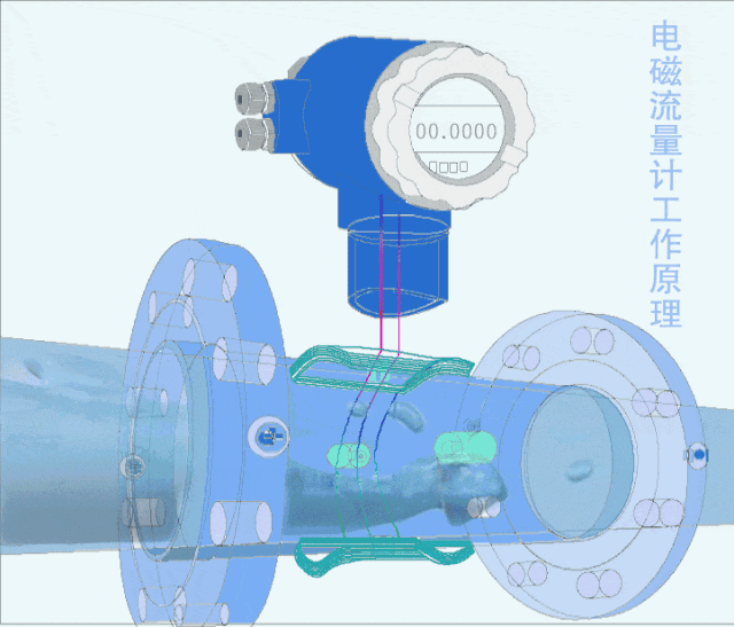

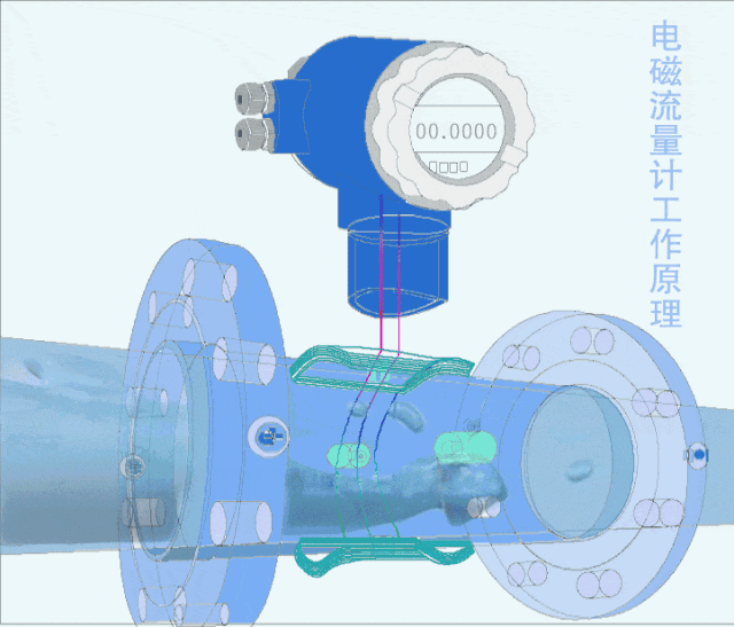

Since the first industrial application of electromagnetic flow meters in China in the late 1950s, their use and development in flow measurement have progressed rapidly during the 1970s and 1980s. The working principle of an electromagnetic flow meter is based on Faraday’s law of electromagnetic induction. This principle states that when the measured medium flows perpendicular to the direction of the magnetic field lines, an induced electromotive force (EX) is generated in a direction perpendicular to both the medium flow and the magnetic field lines. When the magnetic field strength (B) and the distance between the electrodes (d) are constant, the induced electromotive force (EX) is directly proportional to the flow rate (velocity) of the measured medium.

Electromagnetic flow meters are not affected by external factors such as temperature, pressure, viscosity, or density. There is no pressure loss due to constrictions or protrusions inside the measuring tube. Additionally, the initial signal detected by the flow element is a voltage that changes linearly with the average flow velocity of the fluid, independent of other properties of the fluid, which provides significant advantages. Given the characteristics of wastewater, such as large variations in flow rate, the presence of impurities, low corrosiveness, and certain conductivity, an electromagnetic flow meter is an excellent choice for measuring wastewater flow. It features a compact structure and small size, making it easy to install, operate, and maintain. If the measurement system is designed with intelligent features and enhanced overall sealing, it can operate normally even in harsh environments.

1. Overview of Flow

Flow: The quantity of fluid passing through a cross-section in a unit of time. Based on different calculation methods, flow can be categorized into:

Volume Flow Rate (V): When the fluid is expressed in terms of volume, it is called volume flow rate.

lMass Flow Rate (m): When the fluid is expressed in terms of mass, it is called mass flow rate.

lInstantaneous Flow Rate: The flow rate of fluid passing through the pipeline in a unit of time (e.g., t/h).

lCumulative Flow Rate: The flow rate of fluid passing through the pipeline over a certain period of time (e.g., t).

2. Main Features

Bidirectional measurement system

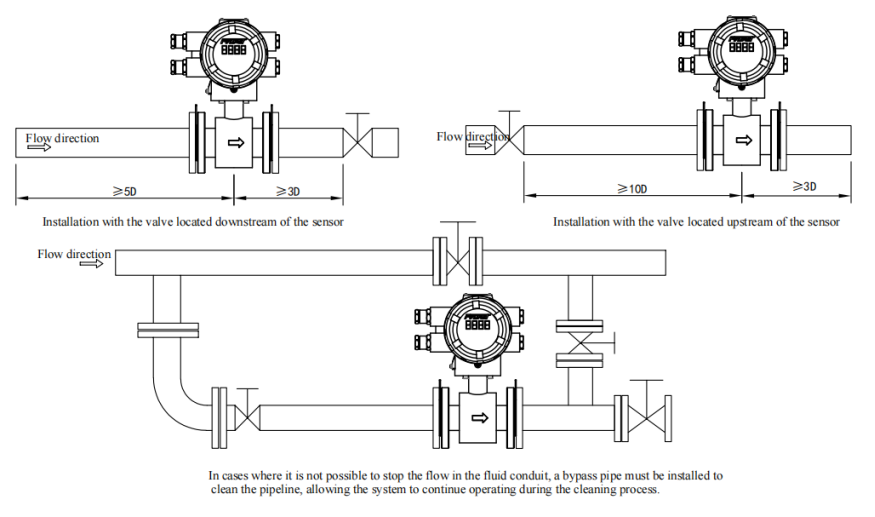

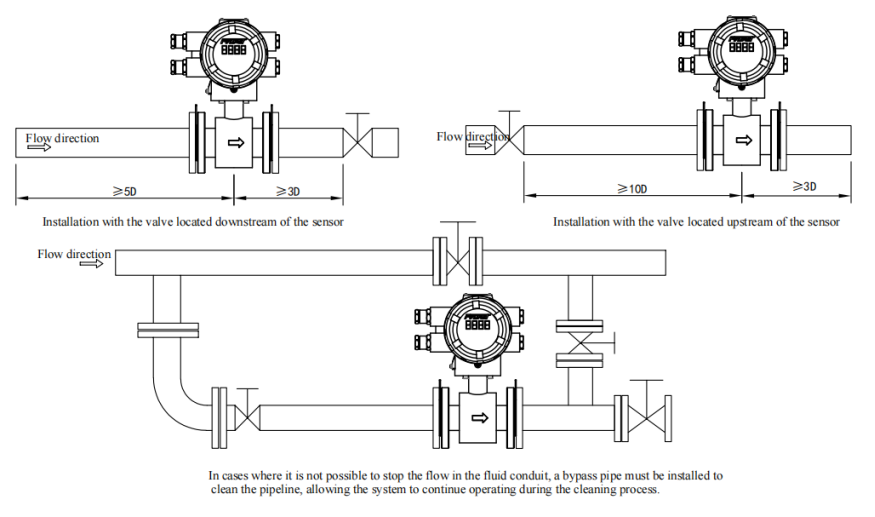

The sensor requires a relatively short straight pipe section, with a length of 5 times the pipe diameter

Low pressure loss

Measurement is not affected by changes in fluid density, viscosity, temperature, pressure, and conductivity

Mainly used in wastewater treatment

3. Key Points for Selection:

Measurement Requirements: Clearly define the required flow range, accuracy requirements, and characteristics of the measurement medium, such as conductivity, corrosiveness, temperature, pressure, etc. This information will help in selecting the appropriate model and specifications of the electromagnetic flowmeter.

Pipeline Conditions: Consider the material, inner diameter, and flow rate of the pipeline, as well as the presence of obstacles such as elbows and valves. These factors can affect the measurement accuracy and stability of the flowmeter.

Environmental Factors: Consider the environmental conditions of the installation location, such as temperature, humidity, and electromagnetic interference. These factors may affect the performance of the flowmeter, so it is necessary to choose an electromagnetic flowmeter with strong adaptability and good stability.

Economics: Select a cost-effective electromagnetic flowmeter based on the budget and long-term operating costs. Additionally, consider the lifespan and maintenance costs of the flowmeter to ensure long-term stable operation.

Precautions:

The measured liquid must be a conductive liquid or slurry.

Diameter and range: It is best if the normal range exceeds half of the full range (generally 4 to 8 times the normal flow), with a flow rate between 2 to 4 m/s.

The operating pressure must be less than the pressure rating of the flowmeter.

Different lining materials and electrode materials should be selected for different temperatures and corrosive media.

4. Advantages

No throttling components, resulting in minimal pressure loss. Not affected by the temperature, pressure, density, or viscosity of the fluid.

Only related to the average velocity of the measured fluid, offering a wide measurement range.

Once calibrated with water, it can measure other media without correction, making it ideal for use as a billing measurement device.

Due to continuous improvements in technology and materials, the stability, linearity, accuracy, and lifespan have been enhanced, and the pipe diameter has been expanded. For measuring media with solid-liquid phases, replaceable electrodes and scraper electrodes have been adopted, solving the measurement issues of high-pressure (32 MPa) and corrosive (resistant to strong acids and alkalis) media. The diameter has been continuously expanded (up to 3200 mm), and the lifespan has been extended (generally more than 10 years). Electromagnetic flowmeters are being increasingly widely used, and their costs have been reduced. However, the overall price, especially for large diameters, remains relatively high, thus holding an important position in the procurement of flow instruments.

5. Disadvantages

Electromagnetic flowmeters cannot be used to measure gases, steam, or liquids containing a large amount of gas. They are also unsuitable for measuring liquids with very low conductivity and cannot measure high-temperature, high-pressure fluids.

The installation and commissioning of electromagnetic flowmeters are more complex and require stricter conditions compared to other flowmeters.

When used to measure viscous liquids with dirt, the viscous substances or sediments may adhere to the inner wall of the measuring tube or the electrodes, causing changes in the transmitter’s output potential and resulting in measurement errors. If the dirt on the electrodes reaches a certain thickness, it may render the instrument incapable of measuring.

6. Main Application Areas

Industrial Automation

Hydraulic Engineering

Environmental Monitoring

Energy Measurement

Popular Field Instruments

Other Field Instruments Articles

Smart Pressure Transmitters

Smart Pressure Transmitters